Wire Mesh Design, Supply, Fabrication and Installation

Locker woven wire mesh is supplied in a range of metals on the roll, cut to size or in strips. In addition to supply, our highly skilled team combine unparalleled experience with technical knowledge to provide a fully bespoke and complete service. Working with architects, designers, planners and main contractors, we develop ground-breaking new applications for our versatile range of materials, as well as providing fabrication, engineering and advice for specific bespoke projects.

Woven wire mesh is strong and durable, with fire resistant properties. It is largely self-maintaining and flexible enough to adapt to fit forms, frames and underlying structures. The majority of our wire meshes are constructed from solid metals and therefore far more fire resistant than comparable composite materials.

We offer a full range of woven wire mesh specifications, from the finest wirecloth filters to heavy duty rigid screens, and our mesh is regularly used within the following sectors for a myriad of applications from tiny filters to huge building facades.

WOVEN WIRE CLOTH & FILTERS

Locker Wire Weavers is a leading industrial woven wire mesh and wire cloth manufacturer, supplier and fabricator. We specialise in woven wire mesh, woven wire cloth and metal mesh used for a vast range of industrial screening, sieving, straining, separating, grading and filtering applications.

WIND SHIELDING

The Locker range of Wind and Weather Shields has been created to provide both permanent and temporary solutions to a range of environmental problems, offering effective wind and weather protection without adversely affecting light transmission or ventilation.

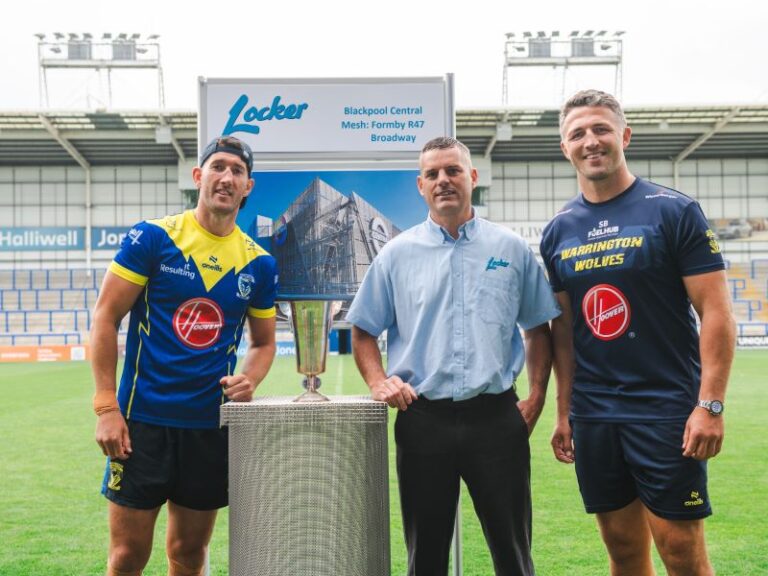

ARCHITECTURAL MESH

Working with architects, designers, planners and main contractors, we develop ground-breaking new applications in the architectural field for our versatile range of woven wire mesh and non-metallic materials as well as providing engineering and advice for specific bespoke projects.

CLARIFIER SYSTEMS

The Locker Clarifier System is designed to reduce suspended solids (S.S.) carry over to lower levels using mesh screening panels. Subsequently B.O.D. (biological oxygen demand) is also reduced in the final effluent produced by sewage and waste water treatment works.RADIANT HEATSHIELDING

Locker Radiant Heat Shield cladding panels provide safety and protection for personnel and equipment against radiant heat from Oil Rigs and FPSO flares. Wire mesh heatshielding panels are lightweight and rigidly structured to withstand the offshore environment and rough handling.

HOBBIES AND CRAFTS

Locker have a business division specialising in smaller quantities of mesh for artists, hobbyists, modelers and home improvers. The Mesh Company also incorporates The Crazy Wire Company and Speciality Metals.

Woven Wire Mesh

Quality and Innovation

Project Experience

Cutting edge technology is combined with unsurpassed knowledge of all things wire mesh to build close partnerships with customers. Locker staff regularly work as part of the project design team to develop new and innovative wire mesh products and solutions.

Worldwide Solutions

Both our resources and our vast applications experience have enabled us to develop wire mesh solutions for many customers worldwide - from blue chip multinational companies to small specialist firms with unique applications.

Corporate History

The Locker Group Ltd has been a leading supplier and manufacturer of woven wire mesh and wire cloth for more than 140 years. Originally established in Warrington, UK in 1878, the quality workmanship and spirit of innovation which defined Locker mesh products then, still hold true today.

For those interested in our corporate history, click on the image of Thomas Locker from our 1928 company brochure (PDF).

Both Locker and Potter and Soar were instrumental in development of the wire mesh industry. Find out more in our article ‘The History of Wire Weaving‘ which documents the progress of the wire mesh weaving industry right from its very beginnings.

Locker Company history Highlights

James Locker invented the first wire cloth weaving machine

Thomas Locker & Co founded in Warrington, England

Locker first to manufacture wire mesh on a steam powered loom

Thomas Locker & Co converted to a limited company

James Thomas Locker elected Mayor of Warrington. Served 1923-25

Warrington site expanded to 14 acres, 7 factories

Locker Company floated on the London Stock Exchange

Purchased sites and expanded business in South Africa, Australia and Belgium during 1953 to 1960

Merged with Butterfield and Harvey, London

First woven wire mesh manufacturer in industry to achieve BS5750 (now ISO9000)

Acquired Henry Simon, Special Products Division

Relocated UK Design and Technical Centre

Strengthened architectural product range through acquisition of Potter and Soar Ltd

Expanded our Farrell St factory facility by 50% to cope with increased demands.

Company Information

Locker Group Ltd registered in England & Wales No.5608946

Locker Wire Weavers Ltd registered in England & Wales No. 420247

Locker Heatshielding Ltd registered in England & Wales No. 5900737

Locker Architectural Ltd registered in England & Wales No. 6752595

VAT Registration No: 896 11 7588